Businesses, including manufacturing, retail, logistics, healthcare, SMEs, etc., face supply chain mistakes more commonly. In 2026, supply chain mistakes will not just happen due to external factors but also due to persistent issues in supply chain management. This directly causes delivery delay, revenue loss, and unhappy customers.

McKinsey reports that poor demand forecasting and lack of end-to-end visibility are among the major reasons for delivery delays and excess inventory, increasing supply chain costs to companies by up to 20–30%. Hence, identifying where these mistakes occur and fixing them early is essential for building resilient, customer-centric supply chains.

Here in this blog, you will get to know the most common issues in supply chain management that are affecting the operations in detail. You will also get to know why these challenges of supply chain management are so common these days. This offers a clear view of how mistakes during planning, inventory control, collaboration, and visibility impact the delivery time, cost, and customer experience. You will also get a clear understanding of practical solutions to supply chain problems and how smarter technology decisions help turn supply chain challenges into a competitive advantage.

What is a Supply Chain - A Short Introduction

A supply chain is the process that involves getting a product from the start to the finish. i.e., from raw materials to the customer's hands. It typically includes:

- Sourcing raw materials

- Manufacturing or production

- Inventory storage and management

- Transportation and logistics

- Distribution to customers

When all the above steps work together, then businesses can move goods faster and at a lower cost. On the other hand, if the data is scattered or visibility is limited and poor, then even the basic supply chain operations slow down.

In order to overcome these issues and get real-time visibility, many companies started relying on end-to-end supply chain software. These systems keep every stage connected and thus help businesses stay focused on providing the best customer experience.

Expert insight: Supply chains perform best when data flows in real time across every stage.

Why Supply Chain Mistakes are So Common Today

Supply chain mistakes are found to be more common at present as supply networks are becoming faster and more global. However, many businesses still rely on outdated systems and processes that are built to handle simpler operations. With the changing customer demands and rising customer expectations, even small delays or data gaps can directly impact the entire supply chain network.

Apart from this, modern businesses also depend on multiple suppliers, logistics partners, and locations. Whenever tools fail to communicate in real-time, teams will lose visibility into what is happening at each stage. This makes it harder to find risks early and respond before the actual delays or cost overruns occur.

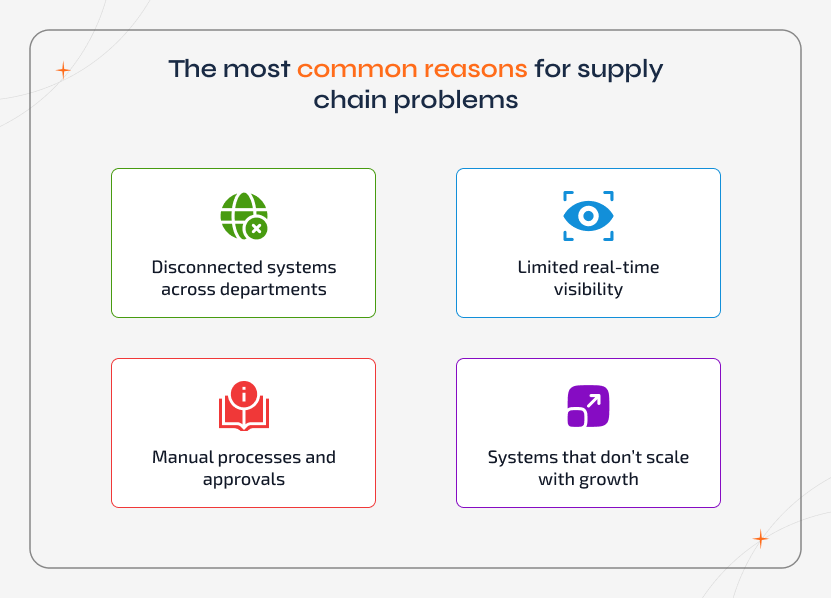

The most common reasons for supply chain problems to repeat include:

1. Disconnected systems across departments

Procurement, inventory, production, and logistics often operate on separate platforms. Thus, they create data silos and slow handoffs.

2. Limited real-time visibility

When there are no live updates regarding the stock levels, orders, and shipments, then decisions are taken based on outdated information.

3. Manual processes and approvals

Spreadsheets and manual workflows will slow down the planning phase, increase errors, and limit responsiveness.

4. Systems that don’t scale with growth

Often, tools that work for smaller operations struggle to handle higher-order volumes, new suppliers, or global expansion.

As global supply chain challenges continue to grow, relying on outdated processes makes these mistakes really difficult to avoid. Hence, addressing the root causes is essential for building more reliable and resilient supply chains.

How Supply Chain Mistakes Impact Core KPIs

Most supply chain mistakes don't just disrupt the operations, but they also directly impact the metrics leadership teams track to measure performance, profitability, and customer satisfaction.

- OTIF (On-Time In-Full) - Delays occur due to poor planning and visibility.

- Inventory Turnover Ratio - Overstocking and stockouts from inaccurate forecasts.

- Forecast Accuracy - Manual planning and disconnected data sources.

- Order Cycle Time - Slow approvals and fragmented workflows.

- Customer Fill Rate - Missed commitments due to inventory and delivery gaps.

Thus, improving supply chain software, real-time visibility, and planning accuracy directly improves these KPIs and overall business performance.

Understand the Real Causes Behind Repeated Supply Chain Mistakes

Learn how outdated systems, poor visibility, and manual workflows create recurring supply chain issues.

Quick Summary of Common Supply Chain Mistakes & Their Impact

Before getting to know the detailed explanations, take a look at the table below as it offers a quick overview of the most common supply chain mistakes, their business impacts, and risk level. With this, decision-makers can find out where gaps really exist in their current supply chain operations.

| Supply Chain Mistake | Business Impact | Risk Level |

|---|---|---|

| Poor demand forecasting | Stockouts & excess inventory | High |

| Inventory mismanagement | Cash flow & fulfillment delays | High |

| Lack of visibility | Missed ETAs & reactive decisions | High |

| Manual processes | Errors & slow scaling | Medium |

| Inefficient returns | Margin erosion | High |

| Ignoring sustainability | Compliance & audit risk | Medium |

| Weak cybersecurity | Operational shutdowns | Critical |

The Most Common Supply Chain Mistakes Businesses Make

Many times, supply chain failure is caused not by one big disruption. They are often the result of repeated, preventable mistakes that slowly weaken planning, execution, and visibility. Given below are the most common supply chain mistakes businesses come across in 2026 and why they continue to cause delays, losses, and unhappy customers.

1. Poor Demand Planning & Forecasting

Whenever the forecasts are not based on real data and are based on assumptions, then businesses end up producing a lot or too little. As a result, they come across excess inventory, missed sales, and delayed production.

Without reliable supply chain forecasting software, companies struggle to handle demand shifts, promotions, and seasonal changes. For all these reasons, poor demand planning is seen as the most damaging supply chain mistake.

2. Inventory Mismanagement - Overstocking & Stockouts

Overstocking increases the storage costs and locks up working capital. Stockouts delay fulfilment and erode customer trust.

This creates an imbalance and often occurs when inventory data is outdated, warehouses operate in silos, and demand signals are not properly aligned. As a result, inventory mismanagement becomes a costly and recurring supply chain problem.

3. Lack of End-to-End Supply Chain Visibility

When teams lack the visibility of what's happening across procurement, production, and logistics, problems often go unnoticed until they become a serious issue. This makes it harder to spot delays, shortages, and supplier risks early. This forces teams to react rather than plan ahead.

Did You Know: If delivery delays are discovered by customers before internal teams, visibility gaps already exist in your supply chain.

4. Dependence on Manual Tracking & Spreadsheets

Manual tracking slows down the decision-making process and thereby increases the errors. The real problem with spreadsheets is that they don't scale, don't update in real-time, and don't support proactive planning.

Those businesses relying on manual tools instead of supply chain tracking software often struggle to respond instantly to disruptions and demand changes.

5. Communication Gaps Between Teams & Partners

Supply chains are all about multiple teams, suppliers, and logistics partners. Whenever communication is poor or fragmented across emails and disconnected systems, updates are missed, and trust breaks down.

As a result of these gaps, delays occur, incorrect shipments take place, and repeated follow-ups take place. These are more common yet avoidable supply chain problems.

6. Over-Reliance on Single Suppliers

Often, relying too heavily on one supplier increases the risk. Any delay, quality issues, or disruption from that one supplier can halt production and affect the entire supply chain. During global supply chain challenges, this risk grows even further as it becomes hard to find alternative suppliers or a time-consuming process.

7. Using Outdated or Inflexible Supply Chain Software

Most often, those existing legacy systems lack automation, integration, and AI capabilities. They can't adapt to changing volumes, new suppliers, and real-time decision-making needs.

Whereas the best supply chain management software provides those key requirements for modern operations, such as scalability, visibility, and predictive insights.

8. Poor Data Quality & Delayed Insights

Those inaccurate, inconsistent, and delayed data often lead to poor decisions across planning, inventory, and logistics.

When there are no real-time insights, then businesses can't optimize their operations or respond at the early stage. This makes the small issues grow into major supply chain failures.

9. Reactive Instead of Proactive Problem-Solving

A lot of times, teams act only after the problems occur. When there is no predictive analytics or alerts, disruptions are often detected at a later stage.

Proactive supply chains use data to identify risks early, reduce downtime, and prevent losses before they impact customers.

10. Delaying Investment in Modern Supply Chain Technology

Postponing investment in AI supply chain software, modern platforms, or scalable systems allows inefficiencies to compound.

Over time, these delays increase the costs, reduce agility, and widen the gap between the customer expectations and operational performance.

11. Hidden Supply Chain Risks Businesses Often Overlook

In addition to the visible mistakes, there are many other issues in supply chain management that remain hidden until the disruption occurs. Some of the common overlooked risks include no contingency or scenario planning, lack of early warning alerts, weak supplier performance tracking, and inconsistent data standards. As supply chains become more digital and connected, cybersecurity risks increase significantly. Even a single ransomware attack or data breach can stop inventory systems, disrupt logistics, and expose sensitive supplier and customer data.

When there is no proactive monitoring, secure architecture, and access controls, these risks increase quietly into serious supply chain problems.

12. Poor Planning & Unclear Processes

When the planning process itself is fragmented and ownership is unclear, then the team proceeds to follow the assumption instead of the data. This leads to missed production schedules, conflicting priorities, and slow response to disruptions.

Those modern planning uses supply chain forecasting software with structured processes and expert alignment between the strategy and execution steps.

13. Inventory Mistakes that Lead to Shortages & Overstocking

Inventory errors often affect the profitability and customer satisfaction directly. Some of the common causes include weak demand signals, disconnected warehouses, and inaccurate stock data. With advanced supply chain logistics software, it is possible to maintain optimal inventory levels, and this becomes the core capability of the best supply chain software at present.

14. Manual Processes and Outdated Tools Hols Supply Chains Back

Manual workflows are no longer seen as a sustainable process. Legacy tools will fail to support real-time decision making or rapid growth. This is why AI-driven supply chain software has become an essential tool. They offer better forecasts, early risk detection, and faster, smarter decisions.

15. Inefficient Returns Management

Most of the supply chains are optimized only for the outbound delivery, and ignore what happens when the product comes back. With poor returns management, inventory mismatches occur and result in delayed refunds, higher logistics costs, and unsellable stock.

When there are no reverse logistics workflows, businesses struggle to track the returned items, assess product condition, and reintegrate inventory efficiently. This, in turn, increases the operational costs and impacts customer trust. With modern supply chain software, it is possible to track returns, inventory reconciliation, and automated restocking.

16. Ignoring Sustainability & Compliance Data

In the current time, supply chains are required to track carbon emissions, ethical sourcing, and regulatory compliance. Businesses that fail to capture this data face audit risks, penalties, and enterprise customer pushback. Manual tracking makes sustainability reporting difficult and unreliable. This creates hidden compliance and financial risks.

Modern supply chain platforms support traceability, compliance monitoring, and sustainability reporting across operations.

17. Neglecting Workforce Training & Operational Readiness

When there is no proper training or operational capacity, even advanced supply chain systems underperform. Staffing gaps, untrained users, and unclear processes lead to data errors and workflow delays. Businesses that invest only in software without change management struggle with adoption and execution. With effective supply chains that align with technology and trained teams, businesses can deliver consistent operational value.

Which of These Supply Chain Mistakes Are Affecting You?

Find recurring gaps in planning, visibility, and systems that may be slowing your supply chain.

How Supply Chain Mistakes Cause Delays, Financial Losses, & Affect Customer Experiences

Whenever supply chain mistakes go unnoticed, they create impacts that spread far beyond the operations. Even the smallest planning gaps or visibility issues will quickly turn into delays, increase costs, and create customer dissatisfaction.

For Example:

A retailer creates a seasonal promotion based on outdated demand forecasts. It has its inventory running in key locations while excess stock piles up somewhere. In order to recover, the business choose for emergency shipments at higher costs. However, the customers will still face delayed orders and poor communication. These mistakes often result in:

- Missed delivery commitments because of late issue detection.

- Higher logistics and inventory costs due to rush shipments and overstocking.

- Revenue leakage appears due to cancellations, stockouts, and lost repeat sales.

- Poor customer experience that causes delays and unreliable order updates.

Over time, these effects compound and affect margins and brand trust amongst the customers. Addressing them even requires a long-term solution to supply chain problems.

The Last-Mile Delivery Challenge:

The final delivery stage, also known as, the last mile, is responsible for over half of total shipping costs and the majority of delivery delays. Poor route planning, lack of real-time tracking, and fragmented carrier coordination lead to missed delivery windows and rising logistics expenses.

Without last-mile visibility, businesses find it hard to meet customer delivery expectations despite if the upstream operations performs well.

How Supply Chain Visibility Impacts Customer Experience

Supply chain visibility plays a major role in shaping customer experience. Customers in the current period are looking for accurate delivery dates, real-time order updates, and clear communication when delays occur. Businesses cannot meet these expectations when there is no visibility across inventory, production, and logistics.

So, when teams lack real-time insight, estimated delivery dates are based on assumptions and not based on actual conditions. This leads to missed promises, last-minute changes, and reactive communication. Thus, customers get frustrated and reduce brand trust. In most cases, customers are notified only after the delay has already occurred.

With end-to-end visibility, businesses can track orders and inventory at every stage of the supply chain. With the modern end-to-end supply chain software and supply chain tracking software, it is possible for teams to

- Offer accurate ETAs based on live data.

- Identify delays early and notify customers proactively.

- Respond faster to exceptions and disruptions.

- Maintain consistent order updates across the channels.

With this, businesses can deliver more reliable service, improve on-time delivery rates, and build long-term customer trust. In competitive markets, this transparency level turns supply chain visibility into a clear customer experience advantage and is no longer just an operational improvement.

How Supply Chain Management Software Helps Prevent These Mistakes

Modern supply chain management software is helping businesses move away from disconnected tools and manual processes by connecting all supply chain activities into one intelligent, connected system. Rather than reacting to problems after they occur, teams gain the visibility and control that are required to prevent these issues early.

Upon centralizing data across procurement, inventory, production, and logistics, supply chain software eliminates the guesswork and improves the coordination across the entire operations. The key benefits include:

1. Real-Time Visibility Across Operations

Teams can track the inventory, orders, and shipment details live. This helps reduce the blind spots and delays.

2. Automated Tracking & Alerts

Systems will identify the delays, shortages, and exceptions at an early stage. Thus helping teams to act before problems escalate.

3. AI-Powered Demand Forecasting

Advanced forecasting models help analyse the historical and real-time data to predict demand more accurately and reduce overstocking or stockouts.

4. Improved Supplier Coordination

Shared data and performance tracking will help align suppliers, reduce delays, and improve accountability.

5. Data-Driven Decision-Making

With accurate, up-to-date insights, decisions are made based on facts and not assumptions or outdated reports.

Upon unifying supply chain operations into a single platform, businesses can stay away from errors, respond faster to change, and build more resilient supply chains. So, teams can focus on optimization, growth, and improving customer satisfaction rather than managing constant disruptions.

ERP vs Supply Chain Management Software – What's the Difference?

ERP systems are used to manage internal business processes like finance, HR, and procurement. Supply chain management software handles everything from planning, execution, to visibility, and optimization processes across suppliers, warehouses, and logistics partners.

Although ERPs provide transactional stability, modern supply chain platforms deliver real-time insights, predictive analytics, and cross-network visibility. Thus, modern supply chain software includes all the capabilities that are essential to prevent operational mistakes.

Why AI Maturity is Now a Competitive Advantage in Supply Chains

Not all supply chain companies use AI in the same way. Many businesses evolve through clear maturity stages, starting from manual operations to intelligent, self-optimizing systems.

1. Manual - Supply chains rely on spreadsheets, emails, and reactive planning. Decisions are made based on past data and instinct. This leads to frequent delays and errors.

2. Automated - Rule-based workflows and basic tracking tools minimize the manual effort. Although operations take place faster, decisions stay reactive and limited to pre-defined rules.

3. Predictive - AI-driven forecasting and risk alerts find the past and real-time data to predict the demand shifts, delays, and disruptions before they occur.

4. Autonomous - Supply chain systems automatically adjust the plans, inventory levels, and logistics execution with minimal human intervention.

Most businesses remain stuck between automation and prediction, leaving real optimization untapped.

How Supply Chain Mistakes Becomes Costly As Business Scales

When businesses start to scale, the supply chain becomes more complex to handle. i.e., more suppliers, more locations, increased order volumes, and higher customer expectations. Even those small inefficiencies that were once manageable can quickly multiply and become a major operational issue.

Companies start to discover that these tools and processes that supported early growth struggle under increased scale. The common scaling-related supply chain challenges businesses come across include:

1. Manual Approval Slowing Expansion

When order volumes increase, manual approval workflows create bottlenecks, delay fulfilment, and reduce responsiveness across teams.

2. Rigid SaaS Tools That Lack Flexibility

Often, those off-the-shelf platforms can't adapt to unique workflows, regional rules, and complex pricing and logistics requirements.

3. Data Silos Across Regions & Partners

Whenever regional teams work on separate systems, business owners lose a unified view of inventory, performance, and risk.

As the above challenges grow, they bring in deeper issues in supply chain management. This includes poor integration, lack of control, and limited scalability. This is the reason for many scaling companies to move towards custom supply chain software development.

Custom solutions are designed in such a way that they work for specific workflows, growth plans, and operational complexity. Thus, helps businesses maintain automation, visibility, and efficiency as they expand.

What Changes in Supply Chains as Businesses Grow

Discover how growth increases complexity and exposes gaps in supply chain processes.

Why Custom Software is the Right Choice for Complex Supply Chains

Off-the-shelf supply chain tools are designed to solve common problems. Although this works well for standard operations, they often struggle as supply chains become more complex, customized, or global. Custom software becomes the best choice whenever standard software can't support your workflows, integration, or growth.

Generic tools often force teams to adapt their processes to the software. This leads to inefficiencies and workarounds instead of solving the exact problem. Hence, partnering with a top custom software development company helps businesses address these challenges effectively by building solutions that work for their exact operational needs.

The benefits of custom supply chain software development include:

- Custom workflows aligned to real operations - Software is designed to match how your teams actually work. They also reduce manual steps, delays, and process gaps.

- Seamless ERP & CRM integration - Custom solutions connect smoothly with the existing systems. Thus eliminating the data silos and supports single source of information.

- Better scalability & security - Systems are built to handle growing order volumes, new regions, and evolving compliance requirements without bringing in any performance issues.

- Long-term cost efficiency - Although the upfront investment looks higher, custom software development often reduces recurring license fees, inefficiencies, and costly workarounds over time.

When a trusted custom software development agency follows agile software development practices to deliver custom solutions, then the solution continuously evolves, adapts to business growth, market changes, and new supply chain challenges. Thus making custom software the future-ready foundation for complex supply chain operations.

Early Warning Signs That Show Your Supply Chain is at Risk

Supply chain failures rarely happen overnight. Often, they show early signals that are ignored until the actual disruptions occur.

Common warning signs include:

- Frequent manual overrides in planning and execution.

- Increased use of expedited or emergency shipments.

- Inconsistent or mismatching inventory reports.

- Missed delivery promises and last-minute changes.

- Declining supplier performance consistency.

Identifying and addressing these warning signs early helps prevent small issues from becoming costly supply chain failures.

Common Supply Chain Software Implementation Challenges & How to Avoid Them

Even after strong intentions, many supply chain software initiatives fail to deliver the expected results. The most common reasons for this are not the technology limitations but execution challenges.

Poor data migration becomes the cause for inaccurate insights and broken workflows. User adoption becomes low when the teams are not trained or involved early in the process. So, la ack of change management brings in resistance and forces teams to look for manual workarounds.

Any successful implementation is all about flexible platforms, phased rollouts, clear data foundations, and better user training. When technology adoption is better aligned with people and processes, supply chain software delivers measurable, long-term results.

Why Choosing the Right Supply Chain Software Matters to Avoid Costly Mistakes

Choosing the right supply chain software directly impacts the business efficiency, scalability, and customer experience. The supply chain mistakes become recurring if the wrong platform is chosen.

To make the right choice, businesses should evaluate more than just features. The key factors to consider include:

1. SaaS vs. custom flexibility

Off-the-shelf tools work initially. But custom solutions adapt better to complex workflows and growth.

2. AI & analytics capabilities

It is possible to prevent problems before they actually occur with predictive insights, demand forecasting, and early risk detection.

3. Integration readiness

The software should be able to connect smoothly with existing ERP, CRM, and logistics systems to avoid data silos.

4. Scalability & security

Whenever operations expand, the platform must be able to handle high volumes, new locations, and compliance needs without performance issues.

5. Total custom software development cost over time

Long-term value matters more than upfront cost. Flexible, well-built systems minimizes the rework, inefficiencies, and licensing fees.

Poor data migration becomes the cause for inaccurate insights and broken workflows. User adoption becomes low when the teams are not trained or involved early in the process. So, la ack of change management brings in resistance and forces teams to look for manual workarounds.

This is where Sparkout stands ahead. With experienced developers, we are involved not just in building software, but we design scalable supply chain solutions customized to your business operations. Our team combines deep domain expertise, agile development practices, and AI-driven capabilities to help businesses avoid future supply chain mistakes and build systems that grow with them.

Choose a Supply Chain Platform That Scales With You

Get expert guidance to select or build supply chain software aligned with your workflows and growth.

What ROI Can You Expect from Modern Supply Chain Software

Investing in modern supply chain management software offers measurable business outcomes when implemented correctly. Businesses adopting advanced supply chain platforms experience:

- 10-12% reduction in inventory holding costs with proper demand planning.

- 15-30% improvement in forecasting accuracy using AI-driven analytics.

- Faster order fulfilment and higher OTIF rates with real-time visibility and automation.

All the above factors directly lower the operational costs, improve service levels, and strengthenHow Supply Chain Mistakes Cause Delays, Financial Losses, & Affect Customer Experiences customer satisfaction. Thus, turning supply chain efficiency into a competitive advantage.

Conclusion

Most often, the supply chain failures don't just start with major disruptions. Rather, they start with small gaps, such as manual tracking, poor planning, or disconnected systems. Over time, these small gaps grow into costly supply chain problems.

So, investing in modern Supply Chain Management Software, leveraging AI, and adopting Custom Software Development, businesses can get better visibility, resilience, and control. Thus, turning supply chain challenges into a lasting competitive advantage.